Hex Bolts (cold/hot forged) DIN

931 / Din 933 |

|

|

| |

Hexagon Bolts are created to DIN 931, DIN933 and are

a threaded fastener with a hexagon-shaped head

that is usually fixed with a spanner or socket tool.

Hosting a machine thread, these bolts are suitable for

use with either a nut or within a pre-tapped hole.

Materials can include various grades of steel, including

Grade 5 (5.6), Grade 8 (8.8), Grade 10 (10.9) and Grade

12 (12.9) with zinc plating, zinc and yellow,

galvanising or self colour. They are also available in

A2 and A4 stainless steel, with other materials

available to order.

As standard, they are available in sizes from M3 to M64,

with non-standard sizes and threads – such as UNC, UNF,

BSW and BSF – all possible to order. |

| |

|

|

| |

| |

Socket head screws DIN 912 /

ISO4014 |

|

|

| |

Hexagon socket head cap screws, DIN 912 These are

classic metric screws with cylinder head and hexagon

socket also known as SHCS. All these screws are 8.8 and

are zinc-plated as a protection against corrosion.

Socket Cap Screws to DIN 912 are often referred to as

Allen head bolts.

They host a hexagonal recess and are driven using an

insert bit or a hex wrench, making the screws more

efficient than the slotted screw products as the hex

socket drive has more resistance to cam out and can be

used with power drivers to enable faster installation.

Higher torque is able to be achieved with the use of

this socket head too. |

| |

|

|

| |

| |

Button Head Screws ISO7380-1 /

Button Head Screws with Flange ISO7380-2 |

|

|

| |

Screw with inward hexagonal grip and a rounded head

and a flange. The flange substitutes a loose washer.

Flange button socket screws Fasteners are protective

fasteners which provide the assembly with structural

support as well as a visually appealing look. It

protects the components around it from damages like

scraps and unintentional cuts. Another advantage of

these screws is the large under head bearing surface -

this eliminates the need for washers. It could also be

considered as a built-in washer. These screws are fully

threaded to provide its users with grip and accurate

positioning.

Although these screws have a considerably high load

bearing strength, it is not advisable to use them in

high strength applications. The stainless steel, carbon

steel or alloy steel make gives these screws an

additional corrosion resistant property. They are mostly

used in applications where the surface area of operation

is not sufficient enough for the usage of a wrench. This

means that they are often used in machining and assembly

processes which do not exert too much torque on its

body. |

| |

|

|

| |

| |

Countersunk head cap screws DIN

7991/ ISO 10642 |

|

|

| |

Socket countersunk head cap screws Fasteners are

mainly used in applications which require a visually

pleasing fastener with minimal load bearing

capabilities. So, please note that these screws are not

intended to be used in high strength applications.

Sockets whose wear resistance is to be protected in the

long run can use these screws instead of high strength

countersunk screws. It is available in stainless steel,

carbon steel, and alloy steel to bear more wear and tear

while also making it more corrosion resistant.

Dimensional Standards:

IS 6761, DIN 7991, BS 4168, BS 2470, ASME B18.3.5M

Size range:

Metric: M3 to M24

Inches: 3/16” to 5/16” |

| |

|

|

| |

| |

Dowel pin / Pull dowel pin DIN 7979

/ ISO 8735, ISO 2328, DIN 6325, DIN 8394 |

|

|

| |

One end of these pins is tapped, and the other is

chamfered for easy insertion. To remove, thread a screw

or tool into the tapped hole, then pull the pin out.

Because they aren't vented, they work best in through

holes. Use them as pivots, hinges, shafts, jigs, and

fixtures to locate or hold parts. Pins are precision

ground for accurate alignment. Breaking strength is

measured as double shear, which is the force required to

break a pin into three pieces.

Pins that meet ASME B18.8.2 specifications conform to

ASME standards for material and dimensions.

Metric pins meet DIN 7979D-m6 specifications.

Steel pins have good strength. |

| |

|

|

| |

| |

Tapper pin DIN 1 A & B |

|

|

| |

Our plain taper pins are made to DIN 1B, we also

offer extractable taper pins to DIN 7977 and 7978. As

well as our stocked taper pins, we offer non-standard

diameters up to a maximum of 32mm, non-standard taper

angles, a ground finish and lengths up to 300mm. We

welcome enquiries for split taper pins, which can be

produced to a customers unique specifications.

With DIN standards the nominal diameter is always the

smaller end and the taper is 2% (1 in 50). We can also

supply to other metric standards, inch sizes or

completely non-standard dimensions. We also stock taper

pins in inch sizes to BS46 Part 3.

Materials:

- Mild Steel

- Hardened Steel

- Stainless Steel 303

- Stainless Steel 316 |

| |

|

|

| |

| |

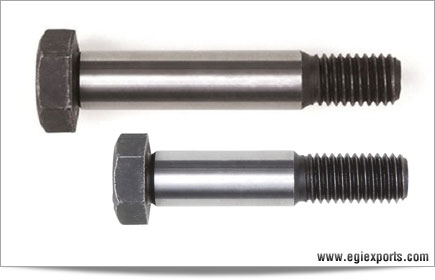

Socket shoulder screws ISO 7379 |

|

|

| |

| Shoulder bolts, or shoulder screws, have a long,

unthreaded, cylindrical shoulder that allows for the

rotation of attached parts like pulleys, gears, moving

parts of engines and mechanical assemblies, and rolling

wheels. These screws are also used to attach stripper

plates. The socket head enables high torque fastening

with limited clearance. |

| |

|

|

|

|

|

|

Hex fit bolts Din 609/ Din 610 |

|

|

| |

DIN 609 Hex Shoulder Bolt (Fit Bolt) with long

threaded portion are in the group Bolts & Cap Screws.

Hex bolts and hex cap screws feature a large fastener

head for distributing clamping load. These fasteners are

used at high tensions and temperatures. Cap screws have

a washer face underneath the head and are used in

precise applications. In Europe, a cap screw refers to a

bolt-type fastener that is fully threaded, whereas a

bolt is the part-threaded equivalent.

DIN 609 Hexagon Fit Bolts with Long Threads is made of

carbon steel, stainless steel A2 and A4. The bolt DIN

609 is installed in the unfolded hole without a gap, so

the neck is pierced by a fine fit and must be ground

after hardening. Such a connection provides not only

accurate positioning of the fastened parts together, but

also the inability to linearly shear. This increases the

service life of the hardware and reduces the risk of

breaking the connection from shearing loads. |

| |

|

|

|

|

|

|

Bushes DIN 172 / DIN 179 |

|

|

| |

| Standard pull out styles are designed for easy

removal when frequent reassembly is required. They have

a smooth finish and are used in applications featuring a

through-hole. Alloy steel is the strongest of all steel

types. It has high tensile strength and offers excellent

resistance to wear, fatigue and galling. Type Standard

Pull Out Material Alloy Steel Pin Diameter (Inch) ... |

| |

|

|

|

|

|

|

|

|

|

|

|